Denmark: A peek at the world’s first cheese robot

We have come a long way with robots. Over the years we have included these mechanical wonders in many aspects of our daily lives. Now, in dairy, the world’s first cheese robot is here to assist.

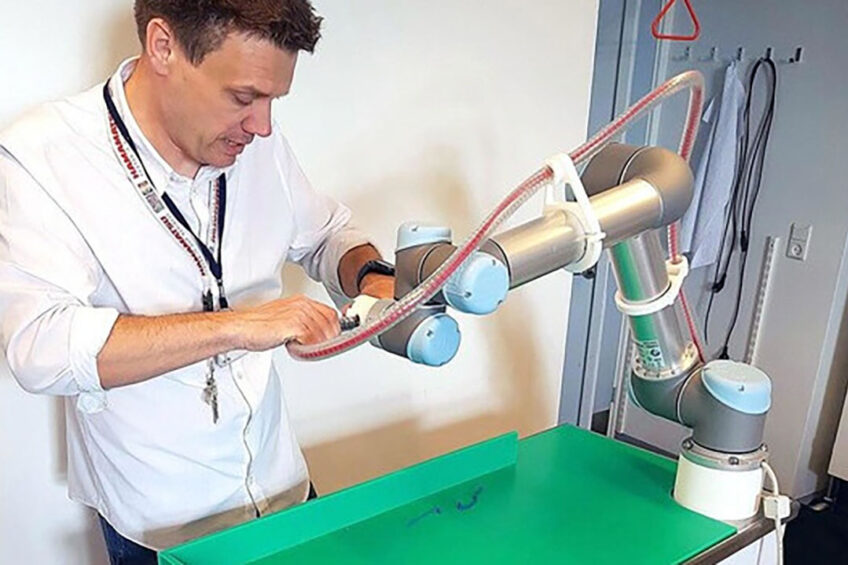

The very first cheese robot is assisting Danish dairy with the quality control of its cheeses, and according to the University of Copenhagen researcher behind the invention, the robot can save dairy companies time and money, while also contributing to more sustainable production in the long term.

The robot has been in use at Arla‘s dairy in Taulov, Denmark, and helping staff produce Danish Havarti, Danbo and Maribo cheeses.

Robot development

Klavs Martin Sørensen, an associate professor at the University of Copenhagen’s Department of Food Science, developed the robot with Arla, the Danish Ministry of Environment and the Danish Dairy Research Foundation to ensure quality and taste for cheeses.

According to the University of Copenhagen, the robot uses near-infrared light through 2 thin metal tubes that are inserted directly into the soft curd. The light emits back wavelengths that are then stored as data about the cheese on a computer.

“Analysing the light allows us to map the chemical fingerprints of a cheese, including its fat, protein and carbohydrate content, among other things. In doing so, we can always see whether cheeses meet the dairy’s quality standards vis-à-vis safety, texture and taste,” explains Sørensen, adding that, “The robot is unique because it monitors each cheese at a very early stage in the process. It can notify a dairy within seconds if something is off, and how, for example, the dairy should adjust a cheese’s recipe for it to be perfected again. We have never been able to monitor this before. So, the robot is the first of its kind and presents a completely new way of working with digital food production.”

Sustainability

Using the robot to test cheese quality is just one part of its use. It can also be used to investigate various sustainable production methods.

“We will soon begin testing whether less water can be used or whether it is possible to recycle some of the water from previous cheeses in production. Here, the robot can help us determine how much water we can save without compromising quality and taste,” says Sørensen.

It is expected that the robot will be ready to be rolled out at several dairies in about a year.

Join 13,000+ subscribers

Subscribe to our newsletter to stay updated about all the need-to-know content in the dairy sector, two times a week.