8 smart methods for dairy cow mastitis detection

Conventional methods of mastitis detection are expensive, arduous, and require samples. Early mastitis detection is essential to minimise economic losses and ensure higher productivity and effective treatment. The recent advancement in technological and engineering tools and materials provides smart effective methods for the dairy industry to automatically detect mastitis.

Augmented reality

Augmented reality

Augmented reality is described as the application of technologies that combine physical and virtual objects over the real environment, interact in real-time, and align physical and virtual objects with each other. Augmented reality provides useful information about dairy cow mastitis by transferring different virtual elements via a computer over the real world.

Infrared thermography

Infrared thermography

Infrared thermography is an emerging, non-invasive diagnostic tool with the potential to detect mastitis in dairy cows. Infrared thermography allows the conversion of the infrared radiation emitted from the udder skin surface into pixel intensity and generates thermographic images of the udder. This method requires specific software for analysis. Research has shown that the udder skin surface temperature of dairy cows suffering from mastitis is about 0.8°C higher than the body temperature. However, factors such as skin color, manure coverage, and hairiness can impact the accuracy and reliability of thermographic results and, therefore, must be addressed to improve the method’s effectiveness.

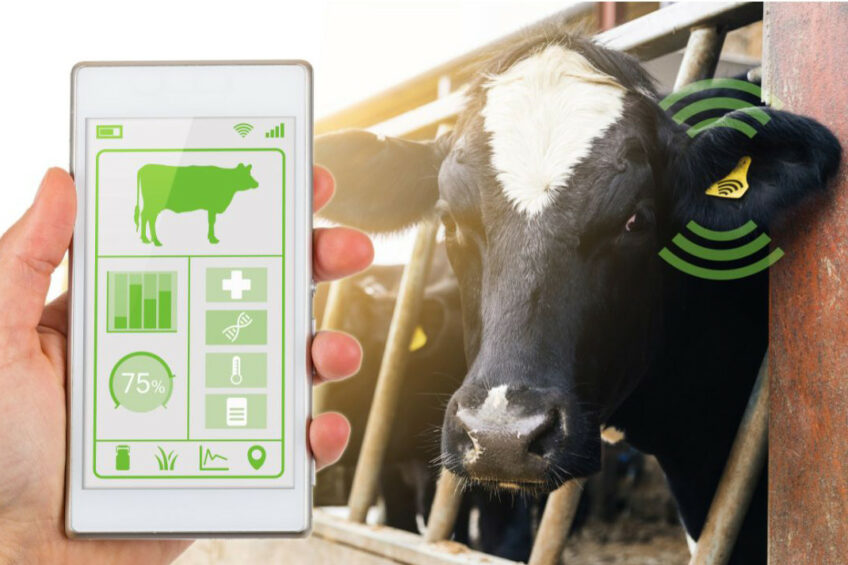

Internet of Things

Internet of Things

The Internet of Things is defined as the ability of connected devices through high-speed internet to sense, collect, share, and process data and utilising this data to fulfil common goals. The Internet of Things infrastructure consisting of wearable sensors such as motion sensors, temperature sensors, and rumination sensors, the cloud system, and the end-user application enables farmers to detect diseases such as mastitis in dairy cows.

Artificial intelligence

Artificial intelligence

Artificial intelligence stimulates human intelligence in machines and exhibits traits such as learning and problem-solving associated with the human mind. Artificial intelligence is used to derive knowledge from data, rationalise, and take actions to achieve specific goals. The implementation of artificial intelligence enables farmers to analyse data collected by sensors for early mastitis detection in dairy cows.

Electronic 3D motion detectors

Electronic 3D motion detectors

Electronic 3D motion detectors are comprised of battery, data transmitter, and one or more sensors mounted on the cow’s body to measure, collect, and transmit physical activity data at specified time intervals. These sensors include ear tags, halters, neck collars, reticulo-rumen bolus sensors, leg tags, tail tags, tail head tags, and vaginal tags. The collected data is computed into physiological and behavioral parameters by algorithms, software, or cloud computing to predict, detect, and diagnose mastitis in dairy cattle.

Deep learning

Deep learning

Deep learning is defined as a subset of machine learning that implements multi-layered neural networks to simulate the decision-making power of the human brain. A computer vision-based automatic recognition model based on deep learning is used for dairy cow mastitis diagnosis. Furthermore, the deep learning network model has an average accuracy of 96.1% in mastitis detection. In addition, deep learning in combination with udder ultrasonography is used as an accurate, rapid, and inexpensive method to detect mastitis instead of routine laboratory test.

5G technology

5G technology

This is the fifth-generation technology standard for cellular networks and can support 1,000-fold gains in capacity, connection for at least 100 billion devices, and a 10-20 GB/s individual user experience of extremely low latency and response times. In intensive dairy production systems, dairy cows can wear a 5G-connected collar that records their activity data and assists with mastitis detection.

Cloud computing

Cloud computing

Cloud computing connects cyber-physical devices in real-time to share data within milliseconds or faster. In addition, cloud computing provides computing services through visualised and scalable resources over the Internet and offers an opportunity to monitor dairy cattle mastitis.

Conclusion

The dairy industry is adopting new technological revolution including augmented reality, infrared thermography, Internet of Things, artificial intelligence, electronic 3D motion detectors, deep learning, 5G technology, and cloud computing to detect mastitis. Although, possible existing limitations in terms of technology and infrastructure in the dairy industry increases the need to advance the devices and tools for more efficient applications in the field.

Join 13,000+ subscribers

Subscribe to our newsletter to stay updated about all the need-to-know content in the dairy sector, two times a week.