Do trace minerals have a role in improving sustainability?

Countless articles over the past 50-plus years have shown the importance of a quality trace mineral program in maintaining optimised dairy cow productivity and health. But what role can trace minerals play as we work to reduce the dairy cow’s carbon footprint?

Before we dig into that question, it is important to mention that achieving mandated, animal nutrition sustainability objectives requires a team effort by all members of the dairy nutrition supply chain. Nutritionists, feed additive companies, ingredient suppliers, feed compounders and producers all need to work together to identify cost-effective solutions to deliver a true reduction in dairy-related CO2eq emissions.

Ongoing research continues to show that several feed additives can lower CO2eq emissions based on their proven ability to improve, primarily, the cow’s feed efficiency. This improvement, coupled with correct ingredient selection within the ration and improved on-farm environmental and management practices, can add up to a meaningful reduction in the CO2eq emissions being produced.

To help dairy producers select the correct combination of factors such as ingredients, additives and management practices, many well-respected, global organisations (e.g., governmental, non-governmental, universities) have united to develop a series of internationally accepted guidelines (FAO, LEAP, PEFCR, IPCC and ISO 14040/44). This allowed for the development of the life cycle assessment (LCA) tool that organises an in-depth review of the ability of an additive, ingredient or practice to reduce the carbon emissions of dairy cattle under a well-defined set of conditions.

The LCA must then be independently evaluated to ensure that the procedure follows the guidelines highlighted above. To provide producers with the most accurate picture of those ingredients, additives and practices (models) recommended for inclusion in their operations, companies must be able to present an independently verified LCA confirming the value of their products and services to assist with the reduction of CO2eq emissions.

Trace minerals impact sustainability

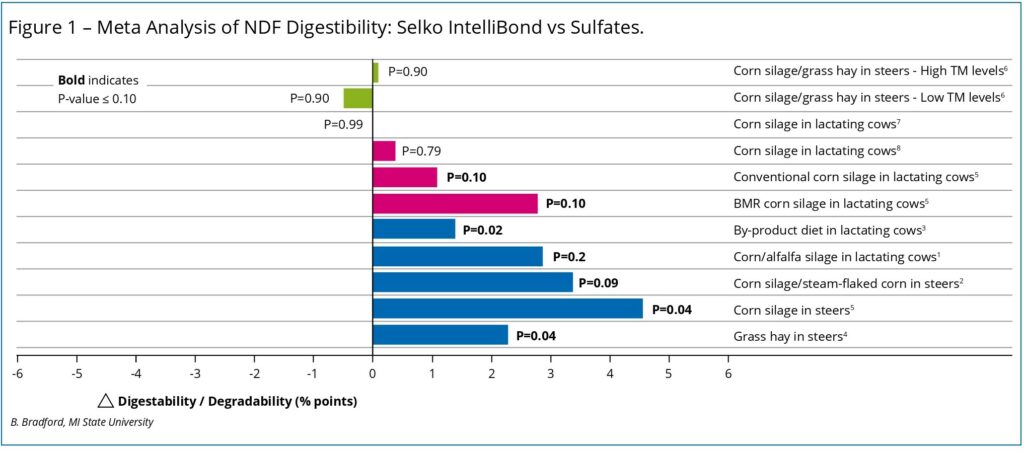

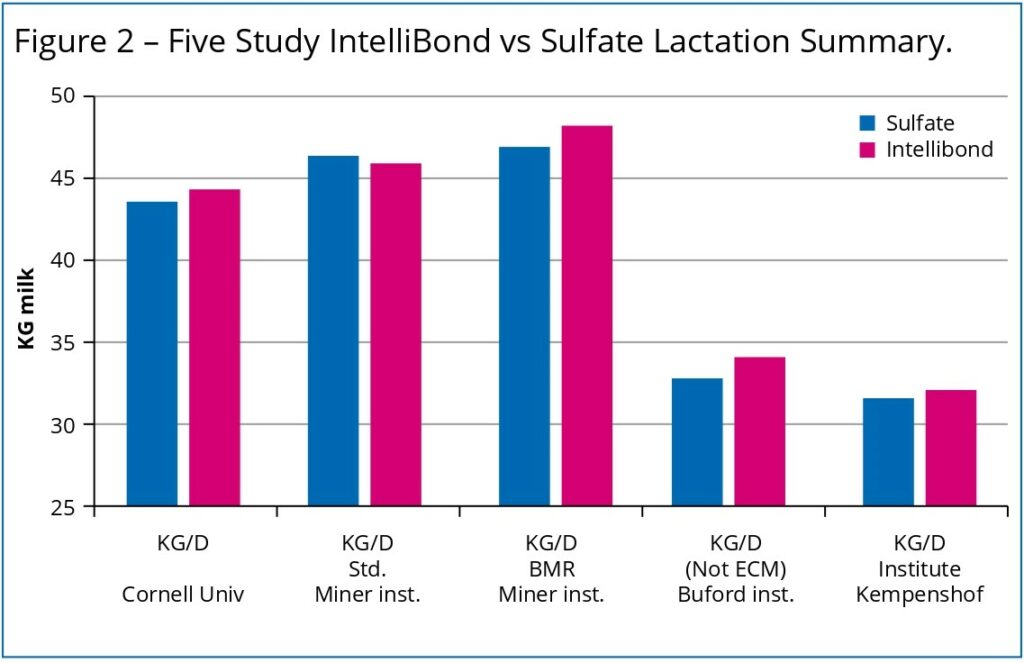

Multiple independent studies have recently confirmed the negative impact of sulfate trace minerals (copper, zinc and manganese sulfate) on neutral detergent fibre digestibility (NDFd) in lactating dairy cows (see Figure 1). This effect results primarily from the antimicrobial impact of soluble copper and zinc, which can negatively react with fibre-digesting microbes in the rumen, reducing ration efficiency. This in turn can have a negative impact on the level of carbon emissions released per litre of milk produced. The same research has shown that when sulfate trace minerals are completely replaced with Selko IntelliBond trace minerals (copper, zinc and manganese) NDFd can be optimised, which can be captured as an increase in energy-corrected milk (see Figure 2).

Based on the positive effect of Selko IntelliBond on NDFd and resulting productivity, Selko completed a comprehensive LCA to measure the ability of Selko IntelliBond to lower the cow’s carbon footprint. The LCA indicated that when Selko IntelliBond completely replaced the use of sulfate trace minerals in the ration, the cow’s carbon footprint was reduced by up to 2%. This result confirms that a quality source of trace mineral nutrition can assist with the reduction of the cow’s carbon footprint. To further verify the LCA’s results, the Selko IntelliBond LCA was independently reviewed by Dr E. Kebreab, Professor, University of California, Davis, confirming that the LCA was compliant with the industry statues.

Based on the positive effect of Selko IntelliBond on NDFd and resulting productivity, Selko completed a comprehensive LCA to measure the ability of Selko IntelliBond to lower the cow’s carbon footprint. The LCA indicated that when Selko IntelliBond completely replaced the use of sulfate trace minerals in the ration, the cow’s carbon footprint was reduced by up to 2%. This result confirms that a quality source of trace mineral nutrition can assist with the reduction of the cow’s carbon footprint. To further verify the LCA’s results, the Selko IntelliBond LCA was independently reviewed by Dr E. Kebreab, Professor, University of California, Davis, confirming that the LCA was compliant with the industry statues.

To meet the needs of feed compounders, premixers and nutritionists who are requesting the total carbon footprint for all ingredients utilised in their blends, Selko IntelliBond completed an additional LCA focused on identifying each IntelliBond product’s total carbon footprint at the conclusion of the manufacturing process. The LCA was independently verified by Dr Kebreab as being correct. Results of the LCA (see Table 1) will provide formulators and nutritionists with the values they require to compare the carbon footprints of various ingredients and additives while maintaining the blend’s nutritional requirements.

As discussed above, achieving industry-focused sustainability objectives is going to require a team effort by all members of the dairy nutrition supply chain. There is no single additive, ingredient or practice that by itself is going to deliver a total solution. Success will demand a group of additives, ingredients and practices be implemented to achieve the final objective.

Selko IntelliBond can be a prime example of this strategy. Adding Selko IntelliBond as the default source of trace mineral nutrition, with its approximate 2% carbon footprint reduction, along with another additive such as 3-Nitro-oxypropanol (3-NOP), which can offer around a 12% reduction in the cow’s carbon footprint, adds up to a 14% reduction in CO2eq emissions. This number can be further increased by adding additional verified nutritional additives, ingredients and practices (for example, genetics) to move closer to a mandated sustainability objective such as a 30% reduction in carbon emissions by 2030.

ROI of reducing the carbon footprint

Unlike some additives that can lower carbon emissions but do not increase cow productivity, Selko IntelliBond does both. Supported by multiple independent studies, Selko IntelliBond’s proven ability to increase essential trace metal availability in the cow while optimising NDFd can result in a consistent return on investment of greater than 10:1. Given that the use of Selko IntelliBond to assist with the reduction of the cow’s carbon footprint does not represent an incremental cost, its true cost to deliver up to a 2% reduction in the cow’s carbon footprint is zero.

In conclusion, selecting the right trace mineral as your default source of trace mineral nutrition can have a positive impact on your goal to reduce the carbon footprint of your operation in a cost-effective manner. Selko IntelliBond can participate as a part of a diverse program of feed additives, ingredients and management practices to assist with reduction of the cow’s carbon footprint.

Join 13,000+ subscribers

Subscribe to our newsletter to stay updated about all the need-to-know content in the dairy sector, two times a week.