Scaling up dairy farming in Finland

It is often the younger generations that want to take big steps. But at Kantoniemen Tila OY, father Juha would like to start scaling up to 600 cows at a new location. Son Joonas and nephew Ville Korhonen are more risk-averse.

Juha Kantoniemi has been farming at the current location in Peränne, Finland, for almost 45 years. He started with his wife Kirsi with 25 dairy cows, expanded to 150 cows around 1995 and to 350 in 2008. The return is structurally high. That is why the company was converted into a private limited company (OY) in 2014. Juha now has 40% of the shares, his wife 9%, son Joonas 26% and nephew Ville 25%.

The financial year runs from March to February. “Many companies work with the calendar year. In December, almost everyone wants to make tax-driven large investments. In February, suppliers will no longer have any trade and will put pressure on prices.”

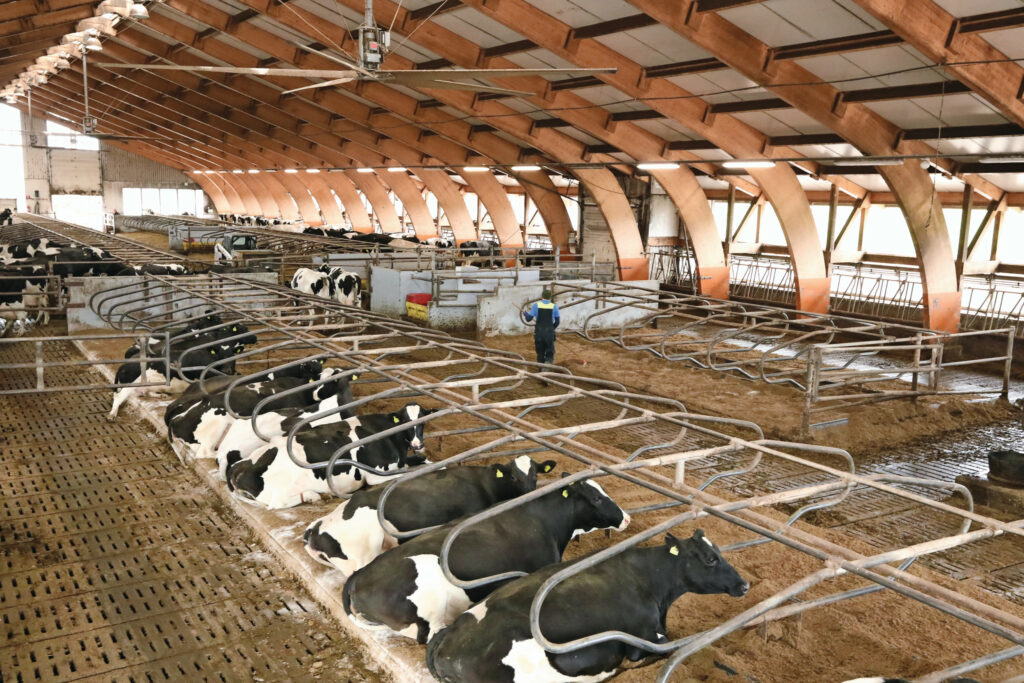

Juha is aiming to remain active in the company for another 4 years, during which hardly any investments will be needed at the current location. The 2 cubicle houses are fully utilised – one is a 4-row, the other a 6-row, with a feed wall on the outside.

“In the 6-row house, that gives too few feeding places. We would build that differently now,” says Juha. It puts pressure on production, but with more than 12,400 kg per cow per year with 3 times a day milking, that is not really a big deal. Certainly not considering the low feed costs of 11.3 cents per kg of milk, 4 cents less than the group average of comparable Finnish companies. This is mainly due to high roughage yields from their own land, which puts pressure on purchases. In addition, the entrepreneurs are not averse to co-products.

Heifers lagging behind

According to the entrepreneurs, rearing young cattle is another bottleneck in business operations. “In the first lactation, milk production remains stuck at an average of 10,800 kg. That is less than 80% of what the older cows do. They average 13,800 kg,” Joonas adds. “I calculate on paper and in broad terms, Joonas and Ville are into Excels and precision,” says father Juha with a smile. He is very happy that his son joined the company after a few years of working outside the home. Cousin Ville was with the company a lot from a young age and grew into it.

Joonas attributes the lagging production of the heifers mainly to the rearing. They weigh the calves at birth and at weaning. The growth up to weaning at an average of 8 weeks is between 900 and 1,000 g per day. After that, however, no more figures are known, other than that the age at first calving is 23.5 months and the production lags behind that of the cows.

Joonas points out the poor housing of the young cattle in particular. The young cattle stables have little capacity and need replacing. But is that really the cause – where exactly is it going wrong? “Now that you have pointed this out to us, we need to get to work on it,” says Joonas. “Collect data. You can only control if you know exactly what is going on, in which part growth is lagging behind. Is that in the summer when the young cattle graze, or in the winter in the stable? We are going to work on that.” He does see an issue arising around weighing the young cattle several times, as the company is not set up for that. “The employees see us coming; they will not be happy about it.”

Field work

Apart from feeding and spreading manure, all field work is done by a contracting company owned by Kantoniemi senior and a neighbouring bull fattener with 1,500 bulls on 500 ha. “At the start, we brought in our machines and about €60,000 in resources,” says Juha. “Since then, we have clear costs and hardly any worries.”

The contracting company works with modern machines, including NIR measurements on the chopper. Nevertheless, the 4 partners have doubts about the data generated. “The employees are not accurate enough; they do not enter all plots correctly, if they enter them at all in a rush.”

The yield of 9 tonnes of dry matter of grass can deviate by about 10%, the entrepreneurs indicate. “We have mapped out exactly what we feed, not what goes into the trench silos of which plot or group of plots.” Banging your fist on the table once, then telling the employees how important data is. “We should, but that is simply not in our nature. We go for peace and good working relationships.”

The entrepreneurs use 500 ha, of which 200 are owned. There is almost a fixed rent of 300 ha at prices between €200 and €350 per hectare. Of the 500 ha, 280 ha are grass, 60 ha winter wheat and about 150 ha spring barley.

In this area, which is 500 km from the Arctic Circle, winter wheat produces about 5-7 tonnes of grain, the spring barley 3-4 tonnes. “We feed 800 tonnes of grain to the cows annually,” Joonas indicates. “We have experimented a bit in recent years. We are fully geared towards silage, which works much faster than grain harvesting and also has nutritional benefits; it provides more structure to the ration. We only continue to combine the barley on plots that are far away from the company because of high transport costs.”

Almost all the grass is artificial pasture: 3 years of grass, then winter wheat and then summer barley with undersowing of grass. Only the young cattle have pasture of around 20 ha. The dry cows have ‘green run-out’ all year round near the cubicle houses with shelter in an arched tent.

Manure disposal is not a problem, although the company is almost at the maximum number of cattle according to legislation. Juha says that, if necessary, additional land can be arranged. There is a lot of manure – around 15,000 cubic metres per year or almost 50 cubic metres per cow, including young cattle due to the open manure silos that are partly at a distance from the company. “We fill them during quiet periods of the year.”

At the beginning of May, approximately 7,500 cubic metres are applied to the land, partly with a drag hose on plots within 2 km of the company, the rest with the slurry tank. The remaining manure is spread after the grass harvest. Despite the northern location, 3 cuts per year are always possible – many years even 4 cuts. The fertilisation of approximately 120 kg of nitrogen from animal manure is supplemented with KAS26 to 200-240 kg of pure nitrogen per hectare, depending on the state of the red clover in the grass. In Finland, the legal maximum is 250 kg of nitrogen per hectare.

The 500 ha cover more than 200 cadastral plots. “With the permission of the landlords, we have reduced the number of plots to just over 100 by, for example, filling in ditches,” says Juha. The largest plot is now 27 ha, but there are also blocks of 0.7 ha. Most plots are within 10 km of the company, the furthest at 40 km. “Most landlords are retired livestock farmers. The majority indicate that they want to sell their land to us in the long term.” Since 2020, 10-20 ha have been purchased each year from the current account. The land price in the region is between €70,000 and €10,000 per hectare. There is not much competition for land. There are 3 other professional companies within a radius of 20 km. “One of them does not seem to have a successor. The other is the bull fattener with whom we collaborate in the mechanisation.”

Fast or slow to 600 cows

In the period 2020-2024, the gross profit year-on-year was between 10 and 12.9 cents per kg of measured milk, with more than 4 million kg of milk annually. This leaves 4 and 5 tonnes per year for repayment and reserves. Note that hardly any resources are needed for replacement investments in mechanisation. The total financing is still around €1.2 million, which brings the equity to a very healthy 65%. All in all, an excellent starting position, also because no resources need to be taken from the company to buy out the daughters.

Juha: “I still have 420 ha of forestry, which will go into a kind of cooperative and will then provide the daughters with a structural income for as long as needed.”

What next? At the current location on the edge of a Natura 2000 lake, growth is impossible, so that has to be done elsewhere. Juha wants to quickly move towards 600 cows at a new location and at most leave the young cattle at the current location in the cubicle houses. “With new construction, we can prevent all the mistakes made in the current stables.” He is heading towards milking robots, because attracting labour is an increasing problem. “Finns no longer want to work in traditional agriculture. With further robotisation and data analysis, I see a way to entice people to come and live here in the woods, far from the big cities.”

The younger generation is less clear about the direction. More cows in the long term are not even a certainty for them. “It is more likely that we will first further increase milk production, towards 15,000 kg,” says Ville. “Only then will other options come into view. We will investigate those. For example, we can build new capacity for 400 dairy cows elsewhere and then milk the fresh cows and the highest yielders here on 2 milking robots in the newest cubicle house. That requires relatively little investment. Then the young cattle can go to the older cubicle house. And we also want to buy land – land remains a solid basis for financing.”

“Times are different, Excel rules,” said Juha. “Joonas and Ville are good farmers, but they could decide a bit faster about the future. They still have 10 years to take big steps. After the age of 45, people don’t make them that quickly.”