Israel dairy farm: “Regulations are becoming harder to comply with”

When Yoel Strauss completed his military service in Israel back in 2007, he couldn’t wait to get back home, milking cows and being more involved in dairying.

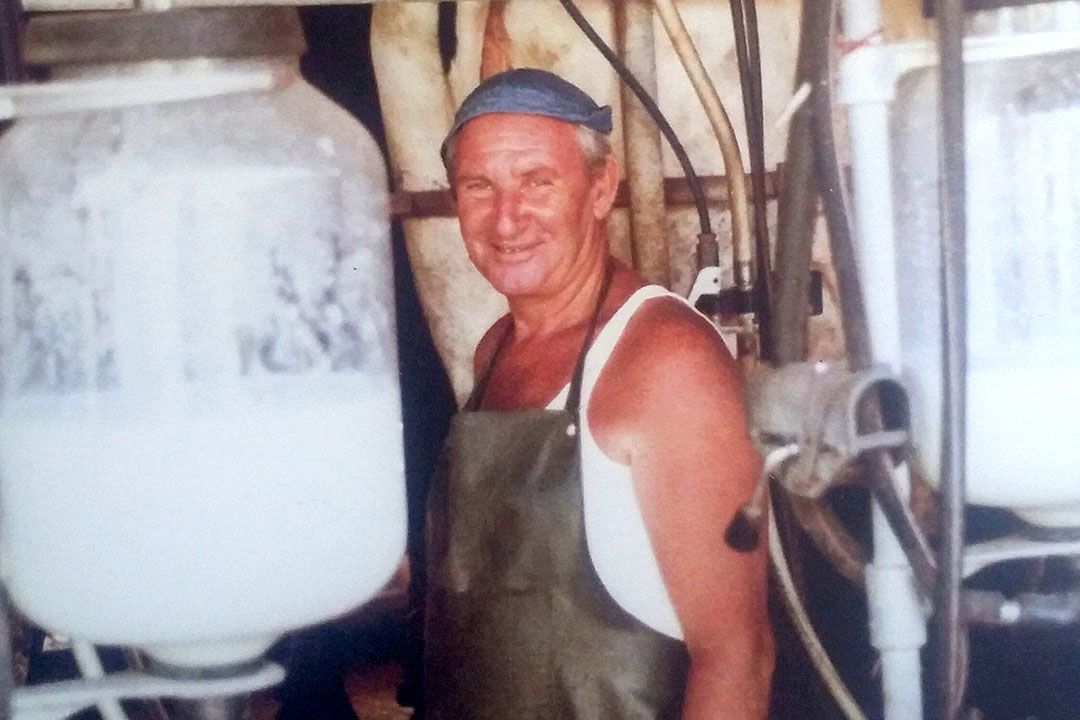

Yoel is the third generation to work on the family farm at Moshav Sede Ilan, following in the footsteps of his dad Ariye and late grandfather, Yitzhak Strauss, known as Itzu. After surviving the Holocaust, Itzu relocated from his native Hungary to Israel and started the farm in 1952. He was allocated 3 milking cows, some chickens and a piece of land by the Jewish agency.

Dairy farm in Israel

Today, the farm runs a total herd of 200 Holstein cows plus 150 replacement heifers. Yoel works part-time on the farm with his dad and brother Yackob, but hopes someday to work full-time keeping the family tradition alive. For the moment, Yoel works as a ruminant nutritionist at Ambar feed mill, and also sometimes with Ofier Langer, the owner of the Israeli dairy school.

Yoel says: “My dad worked with grandad from childhood, combining the farm’s work with managing a regional feed centre producing TMR for cows and sheep. I have worked at the farm all my life and became more involved after finishing army service in 2007. Our farm is only 5 hectares, including 1 hectare of farm shades and buildings. ,Currently my dad manages the farm full-time with my younger brother and I assisting him. We also hire 2 employees from Thailand.”

Israel operates a quota system for its dairy industry and Yoel’s farm has an allocation of 2.16 million litres per year.

Milk production and cow breeding

Yoel adds: “We try to produce most of our milk during the summer months from May to October, because if we overproduce in the winter season we are fined. Our cows are milked 3 times a day yielding 12,000 kg per cow, corrected to 305 days, at 3.8% butterfat and 3.35% protein.”

In terms of breeding, Yoel uses Holstein semen from the Israeli coop Sion on the majority of the herd, around 10% of which is imported from the US.

“For the low genetic cows – around 5% of the herd – we use beef semen, usually Belgian Blue. For some of the heifers we‘re using sexed semen, but on a relatively small scale. All our male calves are sold at 60 days old to another farm in the village to rear.”

The milking herd is split into 2 groups: first lactation and those with 2 or more lactations. All cows are kept indoors year-round and fed a TMR. The milk is sold to Tara, the second-biggest milk factory in Israel. September’s milk price was 2.4 NIS, or € 0.59 per litre. The cows are milked in a 12-by-12 herringbone parlour with Afimilk equipment updated in 2002 and in a shed dating back to 1982.

Feed and technology on-farm

“All our feed comes from a local feed mill owned by one of the village dairy farmers, who mixes the rations with RMH wagons. We use 4 different TMRs – 1 for the milking cows, 1 for growing heifers, 1 for young heifers aged 4-9 months, and a dry cow ration,” he says, adding, “The calves receive 18% protein pellets from Ambar feed mill. And for the cows and heifers close to calving, we add 3kgs of 18% pellets on top of their TMR.”

Yoel likes to keep in touch with the latest technology and last year purchased an Urban pasteuriser wagon to feed milk to the young calves.

As Israel is quite a hot country for cows, most of the farms reinvestment goes into cooling systems and fans to prevent heat stress and other associated problems. Yoel is quite hopeful dairy farming in Israel has a good future, but there are some challenges to overcome if his family farm is to succeed.

Future plans for the dairy farm

“Our future plans include expanding the farm as we have room for 400 milking cows and 250 replacement heifers. Hopefully the milk industry will stay profitable in the future, as we would like to increase production by 100,000 litres each year. By expanding the herd, we hope to build the business to such a stage that my brother and I can work full-time at home.”

Yoel talks about some challenges: “Our problems for the last decade [include] the import of dairy products, as well as raw milk in the last year, from east European countries. [Another] issue is the handling of manure. Regulations are becoming harder and harder every year to comply with, and we need to figure out what to do with all the slurry.”

He continues: “For now, we store all our cow manure in big bunks and spread it on the fields at spring time. As we only have a few hectares of our own, we also deliver manure to a few other farmers close by who grow crops and vegetables.”

Another concern is the introduction of plant-based milk to the markets, says Yoel. “We don’t know how it will affect milk consumption overall, but all we can do is what we did in the last 70 years: produce milk and keep our cows happy,” he adds.

*NOTE: This farm report was written before the recent tensions in Israel.

Join 13,000+ subscribers

Subscribe to our newsletter to stay updated about all the need-to-know content in the dairy sector, two times a week.