Effects of heat stress on fattening pig’s performance and resilience

The effects of heat stress on the swine industry amount to an economic loss of millions of euros each year, making it one of the costliest issues in the pork industry today. Because global warming increases the occurrence of long-term and sporadic extreme temperatures, the detrimental effects on pork production can be expected to become even more of an issue in the future. This emphasises the urgent need to understand the impact of heat stress on production efficiency and to determine mitigation strategies through management and breeding practices.

Thermal comfort zones are determined by the balance between environmental heat load, metabolic heat production, and the animal’s ability to dissipate heat. The latter is complicated by the fact that pigs have a substantial layer of backfat and lack functional sweat glands to facilitate heat loss by evaporation. A pig is within its thermal neutral zone and thermally comfortable when it does not have to resort to behavioural or physiological coping mechanisms to add (cold; e.g., cuddling) vs. eliminate (heat; e.g., laying on a cold floor) additional heat load, or increase (cold) vs. reduce (heat) heat production.

Feed intake and growth

Body heat is generated through metabolic processes that produce heat from growth and maintenance functions to which the animal has some degree of a control. For example, during cold temperatures, pigs can increase their feed intake to support extra heat produced by the heat increment of feeding, i.e., heat produced from the metabolic process of feed digestion. Vice versa, feed intake is often profoundly depressed to reduce metabolic heat production during heat stress. Reduced feed intake furthermore results in reduced growth rates, which further reduces heat produced from their growth metabolism. However, although growth metabolic functions can be reduced to some extent, they cannot be stopped entirely, therefore, it is generally believed that commercial pigs selected for superior growth potential are more sensitive to heat stress because of their greater metabolic heat production.

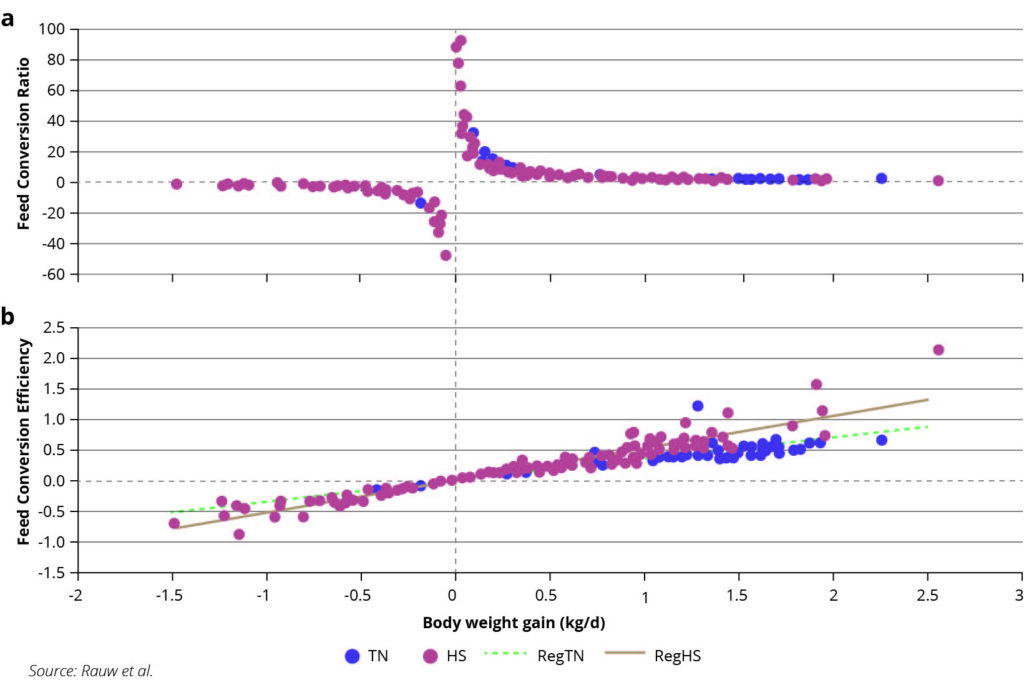

Figure 1 – Feed Conversion Ratio (a; feed intake / body weight gain) versus Feed Conversion Efficiency (b; body weight gain / feed intake) as a function of body weight gain of pigs in a thermoneutral environment (TN) and during heat stress (HS). Figure 1b includes the regression lines (Reg).

Feed efficiency

Feed efficiency is commonly estimated as feed conversion ratio (FCR = feed intake / body weight gain), its inverse, feed conversion efficiency (FCE = body weight gain / feed intake), or as residual feed intake (RFI = the amount of feed that is not accounted for by variation in maintenance and body weight gain). Work at Iowa State University by Rauw et al. showed that in a seven-day thermoneutral environment, as expected in growing animals, (nearly) all pigs gain weight. However, during four-day heat stress, a considerable number of animals gain little or even lose weight. When animals in the population eat to cover maintenance requirements but gain very little or lose weight, FCR cannot be used as a measure of feed efficiency (Figure 1a). Firstly, when gain is just over zero, FCR increases steeply because it is estimated that a very large amount of feed is needed for a full unit of growth (e.g., one kg). Secondly, when weight is lost, FCR takes on a negative value, implying that animals that lose weight are more feed efficient that those that gain weight (note that FCR cannot be calculated when weight gain is zero). In this situation, FCE should be used as a measure of feed efficiency instead (Figure 1b). When weight is lost, also FCE takes on a negative value, now implying that animals that lose weight are less feed efficient than those that gain weight (note that FCE cannot be calculated when feed intake is zero, which is generally not the case during heat stress). In contrast with FCR, FCE values are correctly placed on a continuous scale (Figure 1b). In Figure 1b it can be seen that when animals gain weight, at similar gains, heat-stressed pigs are more feed efficient than pigs under thermoneutral conditions. This can be further explained when we use instead RFI as a measure of feed efficiency (Figure 2).

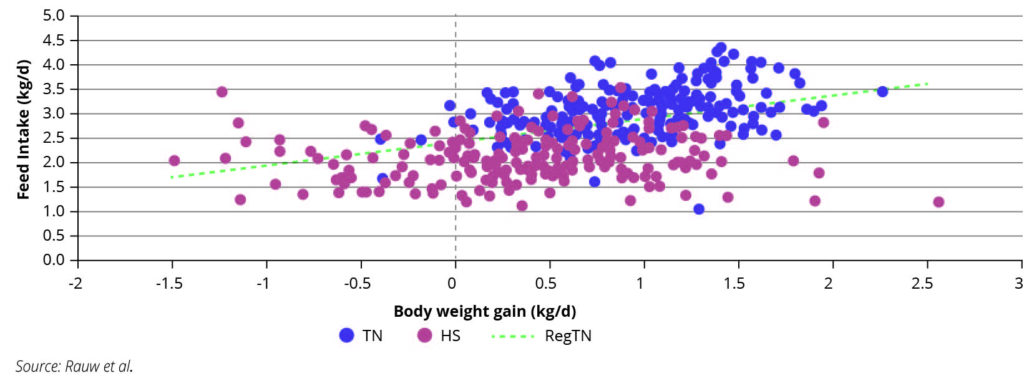

Figure 2 – Feed intake as a function of body weight gain in a thermoneutral environment (TN) and during heat stress (HS). The regression line (Reg) is given for TN.

RFI is calculated as the error term resulting from the multiple regression of feed intake on metabolic body weight (maintenance requirements) and body weight gain (requirements for growth); RFI in growing animals can mostly be explained by differences related to growth. As expected in growing animals, under thermoneutral conditions pigs with higher feed intake have higher body weight gains. Animals that eat more than expected based on their weight gain (i.e., the dots above the regression line in Figure 2) have a higher RFI and are therefore less feed efficient, whereas animals that eat less than expected based on their weight gain (i.e., the dots below the regression line) have lower RFI and are therefore more feed efficient. Note that, when using RFI as a feed efficiency estimate, an animal that loses weight may still be more feed efficient than an animal that gains weight when it is estimated that this individual eats less than that expected based on its weight loss compared with the individual that eats more than expected based on its weight gain. Figure 2 shows that the positive relationship between feed intake and body weight gain no longer holds in heat-stressed animals. Furthermore, heat-stressed pigs mostly eat less than that expected based on their weight gain under thermoneutral conditions, i.e., heat-stressed pigs are more feed efficient because, overall, feed intake is more depressed than growth performance, thus resulting in higher growth per unit feed. For example, some animals can be seen to maintain body weight gain on just over a kilo per day of feed intake. The study carried out at INIA-CSIC & ITACyL by Rauw et al. showed a depression in feed intake of approximately 49 and 28 g per °C in the fattening and finishing stages, respectively. A higher feed efficiency may result from the observation that heat stress is found to decrease relative energy expenditure in growing pigs because of suppression of lipid oxidation in favour of reliance on glucose as a fuel.

Resilience

It is clear that heat-stress-improved feed efficiency is not of desirable origin. Indeed, reduced growth rates, even when produced more efficiently, result in increased time to reach slaughter weight. In addition, heat stress increases carcass fatness due to suppression of lipid oxidation and causes processing issues due to fatness being less rigid, or ‘flimsy’. Therefore, heat stress results in reduced production efficiency. Heat stress furthermore stimulates the typical stress response resulting in increased cortisol metabolism and increased plasma concentrations of adrenaline and noradrenaline, and reduced intestinal barrier function and increased intestinal leakiness which causes local and systemic pro-inflammatory responses. The study carried out at Iowa State University showed that increased growth rates resulted in higher rectal temperatures that reached fever temperatures (40 °C) during heat stress. Indeed, pigs with higher growth rates in the thermoneutral environment were less robust during heat stress.

Selecting for more robust and resilient animals

Thus, heat stress results in stressed animals with impaired health that negatively impacts their welfare. Besides mitigation strategies through improvements in management conditions, we may need to review breed choice and genetic selection objectives when we aim for improved heat tolerance, and the animals of choice may not be the ones with the highest growth potential. Novel techniques, big data analytics, and novel genetics, genomics and -omics and breeding methods may further improve our ability to select animals that are more robust and resilient to climate change.

References are available on request.

Author:

Wendy Mercedes Rauw, PhD, Research scientist, inia-csic, spain

Join 13,000+ subscribers

Subscribe to our newsletter to stay updated about all the need-to-know content in the dairy sector, two times a week.