Benefits of using full matrix values for phytase

Mineral matrix values for phytase have long been used to optimise feed, yet energy and amino acid matrices are largely ignored. With two new studies showing that using their full matrix values can benefit sustainability, that looks set to change.

SUSTAINABILITY & WELFARE SPECIAL 2024 – read all articles

When it comes to sustainability, taking proactive steps to reduce the environmental impact of feed strategies is essential. That means looking at issues related to specific nutrients in dietary feed formulations, such as reducing Nitrogen (N) and Phosphorus (P) waste caused by overfeeding which can affect water quality. It also involves moving away from the traditional use of inorganic phosphorus, as well as opting for locally sourced ingredients rather than relying on complex supply chains with high carbon footprints.

In this context, phytase supplementation is a powerful tool. By improving phosphorus and amino acid digestibility, it can reduce soil and water contamination, as well as tackle problems associated with the higher indigestible fibre content of alternative raw materials. While the fact that the most bioefficatious phytases now have the potential to nullify the need for inorganic phosphorus additives is an equally important sustainability gain.

However, the full value of these products is yet to be fully realised because their recommended nutrient matrix values are often only partially applied. In fact, although phytase is the most widely used enzyme in the animal industry, a significant number of poultry operations focus solely on the mineral fraction (P, Ca, and Na) and ignore both the energy (Kcal ME, MEn, or NE), and digestible amino acid fractions. So by ignoring them, producers are failing to optimise feed efficiency and missing out on significant environmental benefits too.

Given growing environmental concern and regulatory pressure, realising the full potential of phytase enzymes is a key pillar of effective feed strategies. This requires a detailed understanding of their proper use, as well as the precise implementation and application of their full matrix values.

Releasing greater value

Identifying the optimal combination of enzymes depends on factors such as dietary ingredients used in formulations, age, and physiological status of the animals, as well as the operational feed strategy. In all cases, however, the greatest performance benefits are achieved when all three matrix value segments are applied as downspec values from the base diet. In practical terms, this means considering the phytase matrix values first – which acts as the base line – and then adjusting matrix values of the chosen NSP enzyme accordingly.

It goes without saying that selecting a high performance phytase with proven matrix values for different conditions, such as diets, phytate levels, and available calcium content, is essential However, it is important to be aware that not all matrix values are supported by the same robust body of research. Methodologies can vary, as can the number of studies and datasets used to derive the final figures, so working with a reliable and trusted partner is essential. A recent study, for instance, reportedly used 13 datasets to determine the digestible amino acid matrix for a new phytase.

At the same time, it is important to note that current commercial phytases show significant variations in their efficacy at pH levels close to those in the upper gastrointestinal tract (GIT). This is a key point of difference given that the goal is to eliminate the detrimental effects of phytase and its associated anti-nutritive properties as early as possible.

Consideration should be given to the level of phytate (analysed vs calculated), total arabinoxylans (TAX), soluble and insoluble fractions and undigested protein fraction, as well as total calcium content, solubility, and optimal Ca/P ratio. Final calculations also need to be matched with the nutritional strategy of individual operations, to ensure matrix values for the single phytase and combined enzymes are based on these substrate levels.

Review of 2 studies

As part of our ongoing field experience and research programme, we recently carried out two new studies to validate the application of full matrix values for Axtra Phy Gold phytase (PhyG), when used alone and in combination with Axtra XAP (XAP) – a xylanase, amylase, and protease blend – in broiler production.

A total of 3,200 birds were placed across the 2 trials, Exp 1 (0-42 days) and Exp 2 (0-35 days). Diets for Exp 1 was mixed grain based while Exp 2 was corn, soybean meal based and birds were allocated one of four different dietary treatments as follows:

- Positive Control (PC): Adequate nutrient and energy.

- Negative Control 1 (NC1): Diet reduced in Ca, P, Na, ME and Dig AA compared to the PC based on phytase dose recommendation with reductions up to 79 kcal/kg in ME and up to 0.06% Dig AA.

- NC1 and PhyG: Diet were supplemented with phytase at 2,000, 1,500, and 1,000 FTU/kg in starter, grower, and finisher phases respectively (Exp 1) and at 1250 in all phases (Exp 2).

- NC2 + PhyG and XAP: Additional reduction in Dig AA by up to 0.02% and ME by up to 75 kcal/kg. Further supplemented with XAP blend (xylanase at 2,000 XU/kg, amylase at 200 U/kg, and protease at 4,000 U/kg) in all dietary phases.

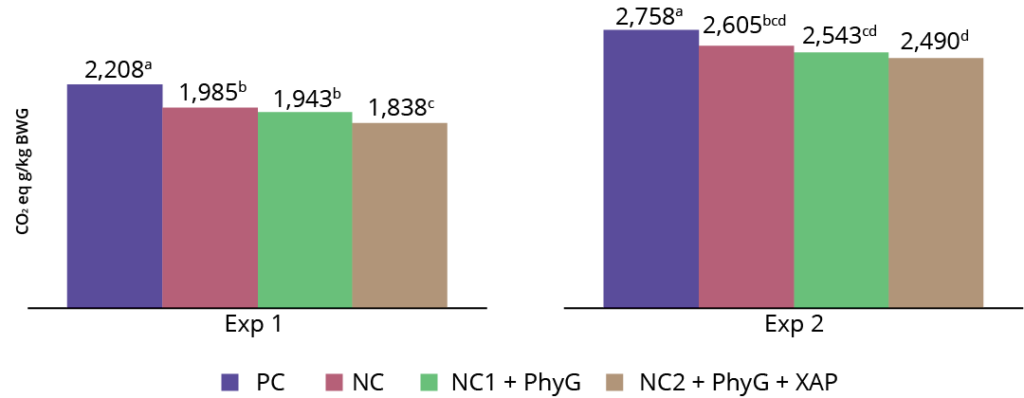

Figure 1 – Supplementation with Axtra Phy Gold in combination with Axtra XAP reduces carbon footprint and could contribute to more sustainable broiler production.

Positive results

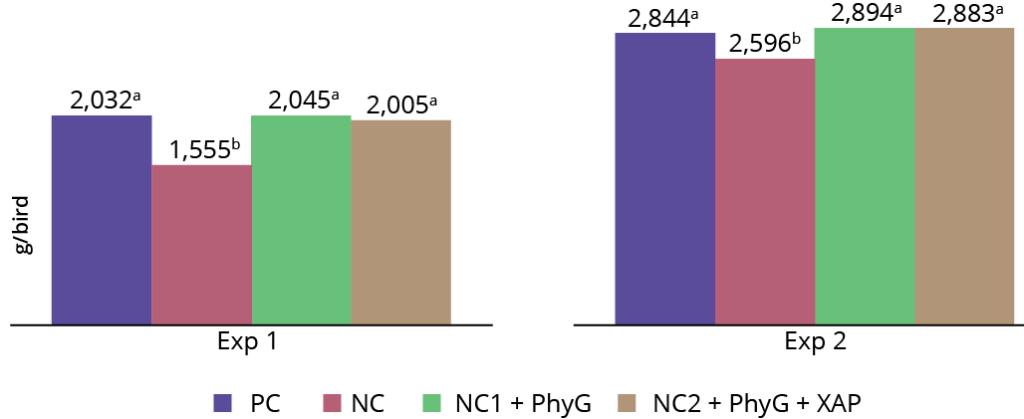

Analysis shows that application of full matrix values for the phytase alone or in combination with the XAP blend maintained broiler growth performance and bone quality, compared to the Positive Control. Moreover, while overall feed costs and total carbon footprint clearly decreased with the addition of phytase, these benefits were further amplified by using a combination of both phytase and XAP blend products.

Positive outcomes of the two studies (Exp1 and Exp2) include:

- Feed cost (€kg BWG) reduced by 10.1% and 12.1%

- Carbon footprint reduced by 16.7% and 9.7% (Figure 1)

- BWG maintained with application of PhyG, while a combination of this phytase with XAP blend provided nutrients equivalent to the NC2 downspec (Figure 2).

Figure 2 – Positive effect of combined matrix application of Axtra Phy Gold and Axtra XAP on bodyweight gain at 42 days.

In conclusion, these results demonstrate that implementing a complete nutrient profile for phytase, by which we mean mineral, energy and amino acid fractions, producers can benefit from measurable production improvements, reduced feed costs, and a more sustainable operation.

References are available upon request.

Join 13,000+ subscribers

Subscribe to our newsletter to stay updated about all the need-to-know content in the dairy sector, two times a week.