What can a fermentation analysis tell you about your silage?

Fermentation analyses are important for assessing silage quality. These reports usually yield clues about the relative number and kind of microorganisms that controlled the fermentation process. The information generated on a fermentation analysis is like a report card on the silage making process and a window into many factors that influenced the quality of the silage, such as: plant maturity, crop moisture, ambient temperature, packing effectiveness, additive use and face management.

Dry Matter

Silage dry matter (DM) is composed of highly digestible sugars, starch, protein and digestible fibre. Harvesting silage at the ideal moisture is critical for properly packing the silo and exclusion of oxygen. Silage DM influences total acid, pH and the type of fermentation process the silage will undergo. Low DM silages may lead to an extended fermentation, excessive protein breakdown and elevated acid levels through the conversion of nutrients. When DM is too high, the forage mass is difficult to pack and tends to be unstable, allowing for yeast and mould growth.

Total Acids

When making silage, the goal is to reduce oxygen so lactic acid bacteria can flourish in order to stabilise and preserve the ensiled forage. Lactic acid is stronger than the other silage acids (acetic, propionic and butyric), and is responsible for most of the drop in pH. Depending on the forage, total acids should be less than 10% of the forage DM, with lactic acid being primary (4% – 7% DM), followed by acetic (2% – 3% DM), propionic (less than 0.5% DM) and butyric (less than 0.1% DM).

Low lactic acid concentrations may indicate restricted fermentation due to high DM content. This is common in legume and grasses with a DM greater than 50%. Restricted fermentation due to cold weather and silages high in butyric acid (clostridial silages) are usually low in lactic acid as well. High acetic acid levels (greater than 3 – 4% DM) are often observed in silages that are ensiled with a very low DM (less than 25%). These types of silages undergo prolonged fermentations due to their higher buffering capacity and loose packing. In such cases energy and DM recovery is less than ideal. Acetic acid concentrations can also be elevated when a Lactobacillus buchneri inoculant is applied to the forage. This is because L. buchneri inoculants convert lactic acid to acetic acid and other compounds.

Inoculants containing L. buchneri aid in yielding a controlled acetic fermentation. Such inoculants are employed to address aerobic stability issues due to spoilage when the silage is exposed to oxygen, especially at feedout. When butyric acid concentration exceeds 0.5% of DM, this is an indication that the silage has undergone Clostridial fermentation. Silages that have high butyric acid are generally low in nutritive value and higher in ADF and NDF levels because many of the soluble nutrients have been degraded.

pH

A key criteria for evaluating silage fermentation is the speed of pH drop and terminal (final) pH. Generally, the lower the pH, the better preserved and more stable the silage. The pH of an ensiled sample is a measure of its acidity, and this is affected by the buffering capacity of the crop. Legume silages tend to have a slower decline in pH, a higher final pH, and take longer to ensile due to their buffering capacity compared with corn and other grasses. An elevated pH due to restricted fermentation is not always indicative of poor fermentation or poor silage, but rather silage that went through a restricted fermentation has a tendency to be unstable when exposed to air.

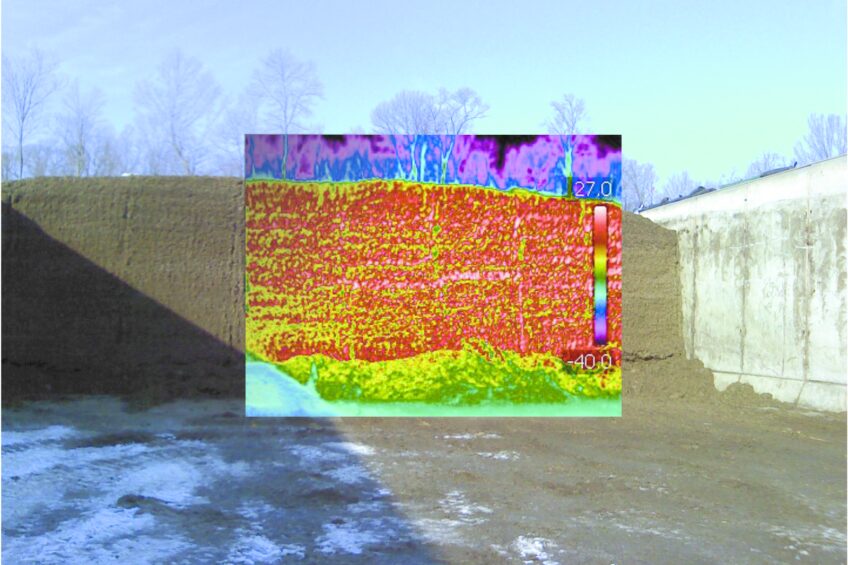

Forage Density

Although not reported on a fermentation analysis, forage densities speak volumes to the quality of the silage in the silo. Poorly packed silage is less dense and allows more air into the silo and thus takes longer to ferment. The longer the forage takes to ferment the more fuel (sugar, starch and protein) is burned. Additionally, less dense forage is also less stable at feedout.

Planning

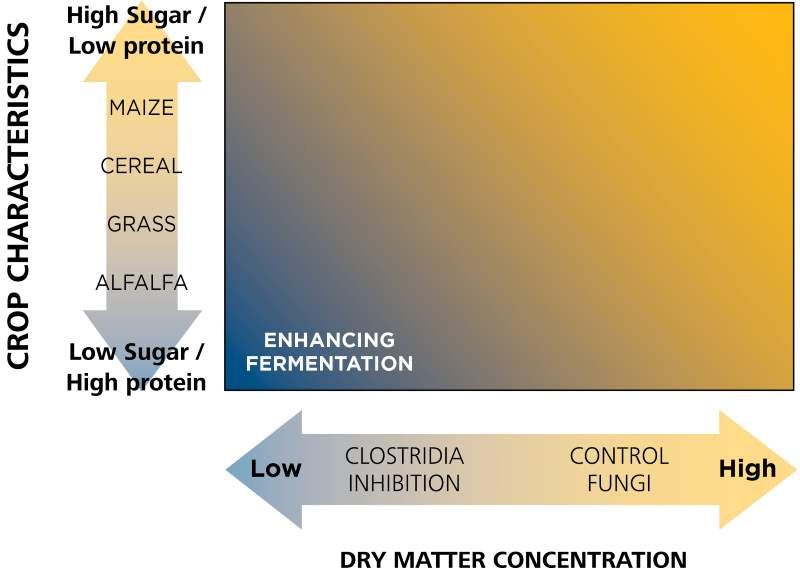

If a fermentation analysis uncovers areas for improvement, start planning immediately. Harvest silage at the ideal moisture, chop length and deliver it to the storage facility quickly. Pack the silo tightly and seal it quickly to ensure it is free of oxygen. Many of the challenges producers encounter are not crop specific, but rather characteristics of the crop at the time of ensiling. Forages with high protein and low sugar ensiled at high moisture may result in poor fermentation.

In contrast, forages with high protein and low sugar ensiled at low moistures may result in heating of the silage during feedout. Chr. Hansen’s function-specific line of SiloSolve® forage inoculants takes into account the sugar, protein and moisture content of the crop at ensiling to optimise fermentation, maximise dry matter retention and preserve nutrients during feedout.