Milk fatty acids and influence on dairy products

Milk fat is a complex mix of fatty acids that contribute to and influence the properties of manufactured dairy products. Despite dairy diets typically containing only 5 primary fatty acids, as a result of ruminal biohydrogenation, milk fat can contain over 400 different fatty acids, each with its own characteristics and physical attributes. These differences can elicit changes in functionality of milk fat and on the dairy products they are used to manufacture.

Milk fat is composed of fatty acids originating from 2 main sources:

1. De novo synthesis – fat manufactured in the udder from acetate and butyrate resulting from digestion of fibre in the rumen. This accounts primarily for the short and medium-chain fatty acids of 4 to 14 carbons and about half of the palmitic acid (C16:0) in milk fat.

2. Dietary fat – direct supply of fat from the diet accounts for the other half of the C16:0, as well as the 18-carbon (and above) fatty acids in milk fat. Approximately 50% of milk fat originates from dietary fat.

A varying proportion of milk fat will arise from mobilisation of body reserves; a higher proportion originates from this source in early lactation when cows are in negative energy balance than in later stages of lactation.

Milk fatty acids

The primary fatty acids in milk and their melting points are presented in Table 1. The predominant fatty acids are the high melting point saturated fatty acid (SFA) C16:0 and the much ‘softer’ unsaturated fatty acid (USFA) C18:1, which also show large potential variability.

Factors affecting fatty acid profile of milk

Season

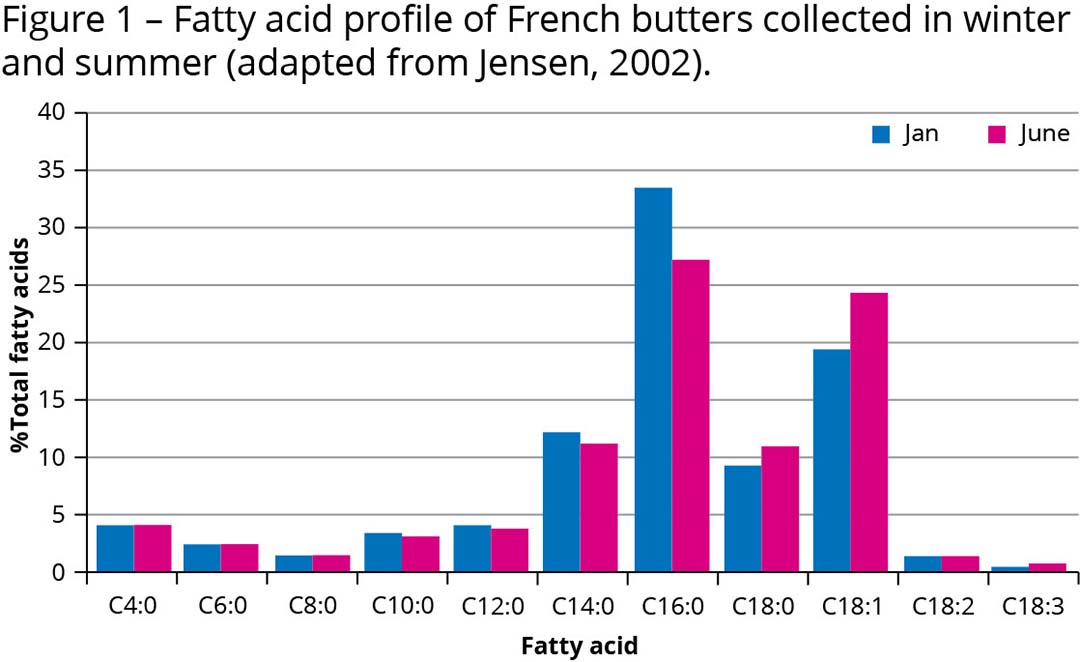

Seasonal effects largely reflect changes in forage source as diets transition from plentiful summer supplies of highly-unsaturated fatty acids from grazed grass to ensiled forages and other ingredients. Summer milk (June) is typically lower in SFA and higher in USFA than milk from cows offered winter diets (Jan), with particular effects on C16:0 and C18:1, and effects are carried through to manufactured dairy products (Figure 1).

Seasonal effects largely reflect changes in forage source as diets transition from plentiful summer supplies of highly-unsaturated fatty acids from grazed grass to ensiled forages and other ingredients. Summer milk (June) is typically lower in SFA and higher in USFA than milk from cows offered winter diets (Jan), with particular effects on C16:0 and C18:1, and effects are carried through to manufactured dairy products (Figure 1).Stage of lactation

The milk fatty acid profile changes considerably throughout a lactation cycle. Early lactation cows in negative energy balance mobilise fatty acids from adipose which are incorporated into milk fat, resulting in inhibition of acetyl-CoA carboxylase and consequently de novo synthesis of shorter chain fatty acids (with the exception of C4:0). With increasing positive energy balance through lactation, the contribution of long chain preformed fatty acids is reduced.

Breed

Genetic background of a herd can influence the blend of fatty acids in milk, adding variability to the supply base. Jersey cows produce milk with higher de novo-synthesised fatty acids, C16:0 and overall SFA, and with lower USFA, than that of Holsteins.

Rumen-protected fat supplements

Rumen-protected fats, developed to overcome the negative effects on rumen fermentation and fibre digestibility associated with unsaturated ‘rumen-active’ oils, have been added to dairy rations for several decades. The most common are palm-based supplements providing concentrated (>80%) levels of C16:0 (‘high-C16’ supplements), blends of C16:0 and C18:1 as with the calcium salt formulations, or hydrogenated products predominating in C16:0 and C18:0. Coincidentally, these are also the prime fatty acids in milk fat (Table 1).

‘High-C16’ supplements are particularly stimulatory for milk fat synthesis, while the calcium salts additionally deliver C18:1 to the small intestine where effects include improved total dietary fat digestibility, body condition and fertility.

Fat supplements and dairy products

Effects of a range of fat supplement types on production and manufactured dairy products were evaluated by Prof. Gervais’ group at Laval University, Canada (Table 2). The stimulatory effect of the ‘high-C16’ supplement on milk fat was clearly evident, though subsequent butter hardness was increased and spreadability decreased.

In contrast, soya oil inclusion in the diet resulted in a substantial reduction in milk fat percentage, but considerably softer and more-spreadable butter. The calcium salt supplement, with a blend of C16:0 and C18:1 fatty acids, maintained milk fat and numerically reduced butter hardness while simultaneously improving spreadability.

This data indicates the potential of dietary fat supplements to alter the physical properties of dairy products and how strategic use can be considered to target specific milk fat attributes according to end use of the milk in manufacturing. However, major changes in the proportion of ‘softer’ fatty acids in milk may have a negative effect on functional properties of milk fat, in which ‘harder’ fatty acids such as C16:0 play a fundamental role.

Biological regulation of milk fatty acids

Regardless of the range of factors affecting fatty acid profile of milk, regulatory biological mechanisms operate to ensure that milk fat remains fluid at body temperature, such that the effect of any individual fat supplement, diet or system change on increasing hardness of milk fat, and consequently potential influence on manufactured dairy product, is necessarily limited.

The ability to manipulate milk fat concentration is a key element of dairy nutrition, but producers and processors should also collaborate to determine the most appropriate fatty acid profile of milk supplied in order to best meet the end product requirements when milk is used in manufacturing.

References available on request.

Join 13,000+ subscribers

Subscribe to our newsletter to stay updated about all the need-to-know content in the dairy sector, two times a week.