Improve dairy cow efficiency: 5 silage management practices

Silage management can support both the quality of the TMR and dairy cow efficiency. Managing the microbial balance in silage is essential, as bacteria, yeasts, and moulds in fresh forage contain both beneficial and harmful microbes. If the balance is disturbed or the amount of oxygen after harvesting is too high, acidification processes will slow down, establishing favourable conditions for harmful microorganisms to proliferate. Adverse effects can include a bad smell, an increase in silage temperature and ultimately reduced palatability and nutritional value of the dairy ration.

Crop contamination may occur in the field, during harvesting, following ensiling, after opening the silage or in the TMR. The following are 5 practices to support silage management.

Manage the crop before harvesting

Manage the crop before harvesting

Avoid surface application of slurry within 10 weeks of mowing. With grass silage, aim for an optimal yield with the correct level of sugars. Residual fertiliser increases the buffering capacity of grass, which slows down the acidification process. Applying adequate amounts of fertiliser at least 8 weeks before mowing helps to manage this challenge.

Excessive wilting can contribute to higher levels of dry matter in silage. As this can encourage aerobic activity, high levels of dry matter should be avoided. Low moisture levels can also reduce the ability to dissipate the heat of ensiled material. If dry matter is above 30%, fine chopping makes it easier to exclude air once the crop enters the silage bunk. Don’t over-irrigate corn in the field since fermentation risk increases as corn matures. Harvest corn silage before it reaches the dough stage.

Reduce contamination risk at harvesting

Reduce contamination risk at harvesting

Don’t delay filling silos or harvest too much crop in a single session. Rapid silo filling reduces spoilage and increases dry matter recovery. Additionally, rapid filling results in increased lactate levels and lower levels of butyric acid in silage.

Avoid soil contamination during harvesting, as soil can be a source of anaerobic bacteria such as clostridia. The silage storage space should be clean with a smooth surface, and no leaks. To reduce oxygen exposure post-filling, apply plastic lining to the silo’s side walls. Adapt the tractor weight and harvesting speed for good compaction. Optimal silage packing density is around 240 kg/m3

Reduce undesired growth of micro-organisms

Reduce undesired growth of micro-organisms

Actions taken after ensiling can reduce oxygen exposure and stimulate the growth of beneficial lactic acid producing bacteria. Ensure the silo is sealed quickly after harvesting. Use plastic of at least 125 microns, cover with soil and/or tyres and use side sheers. To keep the clamp airtight during storage, repair any damaged areas.

Long, narrow silos instead of short, wide ones, allow a rapid feeding rate once silage is opened. The silage face should advance at least 10 cm/day in cold conditions, and 30 cm/day in warm conditions.

Inoculants can help stimulate the growth of lactic acid forming bacteria. Silage inoculants based on lactic acid bacteria can improve aerobic stability and fermentation characteristics.

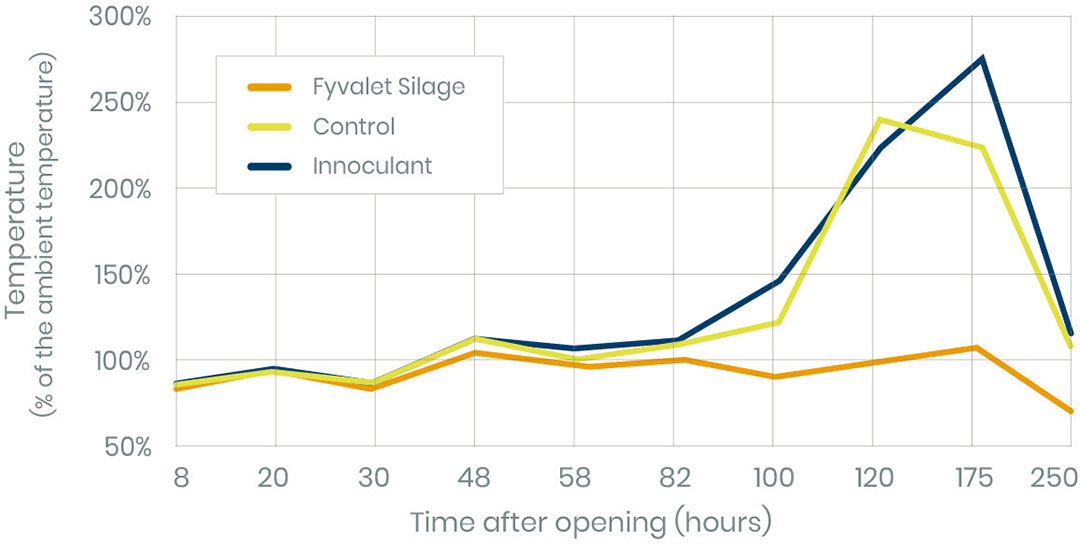

Additives containing organic acids will prevent aerobic deterioration, but not all organic acids are equal, and efficacy depends on the chain length of the organic acid. Certain blends are more suitable for crops with a high dry matter content and relatively low levels of easily fermentable sugars. Crops with a high moisture content and/or high level of easily fermentable sugars require different organic acid mixtures. Certain blends improve temperature stability (see Figure 1), supporting silage’s longevity after opening.

Figure 1 – Stability of untreated silage, a silage inoculated with lactic acid bacteria and silage treated with Fyvalet Silage. Silage was opened after 6 weeks of storage and the temperature was measured at regular intervals for a period up to 250 hours. A value of 120% represents an increase by 3˚C.

Conduct silage testing

Conduct silage testing

Testing silage supports correct ration formulation and is a good indicator of forage and silage management quality (Table 1).

Optimise silages for feeding

Optimise silages for feeding

Cutting the silage so that its face remains smooth will allow less air penetration. Treat the cutting surface with organic acids to slow fermentation. If air leaks into the silo, mould growth may occur, particularly at the top layer and sides. Spraying organic acids on top of the silage can reduce the risk of mould formation.

Avoid letting the covering sheet dangle during feed out to avoid silage falling in front of the cutting edge. Clean up loose material that spills in front of the cutting surface. Keep the sheeting close to the face of the silage between feed out periods.

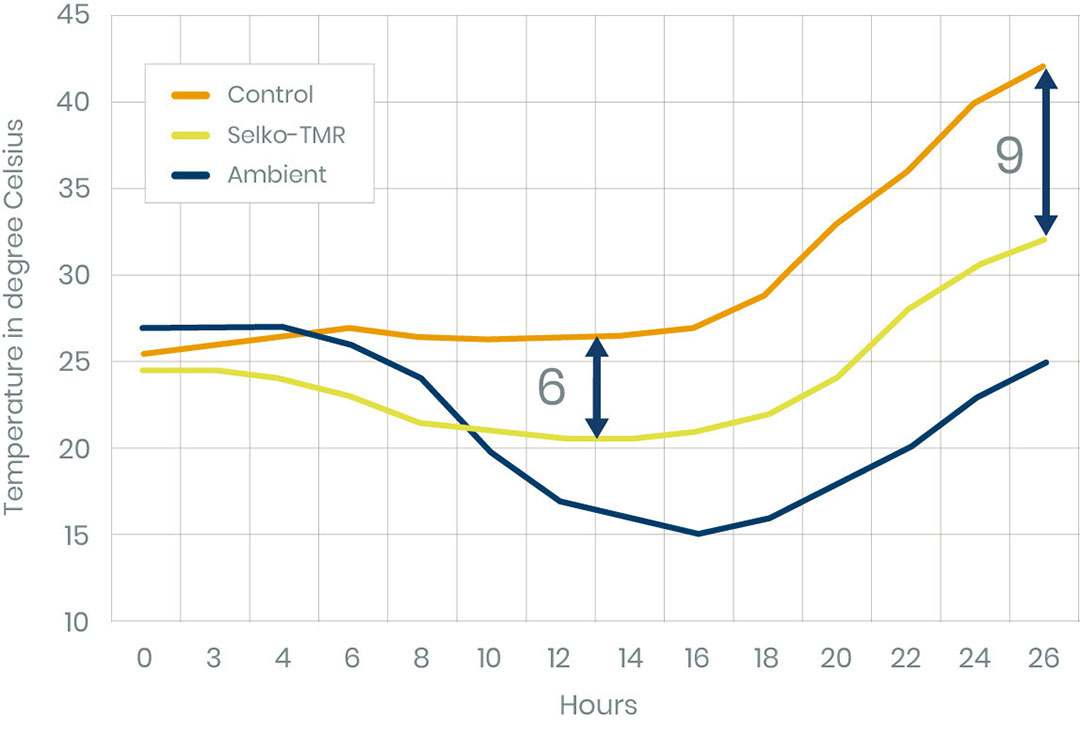

Feed dairy cattle twice daily to reduce silage’s exposure to oxygen. Mix organic acids into the TMR to reduce growth of micro-organisms (see Figure 2).

Figure 2. Temperature development of a TMR treated with Selko-TMR, compared to an untreated TMR. At 12 hours after feeding, the temperature of the TMR treated with Selko-TMR is 6˚C below the temperature of the untreated silage. At 24 hours after feeding, the difference is 9˚C.

Following the five silage management practices above can support TMR quality and dairy feed efficiency.