Dairy farmers’ guide to good hygiene practices

Many countries around the world have strict dairy production hygiene guidelines, but there are many that do not. However, every single dairy farmer is responsible for the safe production of food and therefore should ensure their facilities and animals adhere to hygiene regulations.

Regulations are drawn up for a very good reason: to protect consumers from unwanted bacteria that could enter the production line and have very dire consequences.

Although many countries around the world have strict dairy production hygiene guidelines and inspect farms regularly, many do not.

Even worse, many farms around the world do not practise any form of basic hygiene and can be ticking timebombs for food contamination and outbreaks of food poisoning.

Good hygiene practices apply not only to the actual equipment that milks the cows and stores the milk. Farmers should also keep their dairy barns and cow accommodation clean, dry and well ventilated. They should also ensure the cows themselves are clean, well fed and in good health.

Milk contamination

Firstly, it’s important to understand how milk can become contaminated in the production cycle. The farmer can then take preventative steps to ensure contamination does not happen. Once it does, it is too late.

Milk can become contaminated at any point of the production process. The key sources of contamination are faecal contamination from dirty animals, especially from teats, udders and tails.

Poor milking practices and dirty operator hands or equipment are also sources of bacterial contamination. Failure to detect abnormal milk – such as mastitis, blood and clots – also causes contamination, as does inadequate cleaning of the system and bulk tank.

Perished equipment, such as filters or the rubber hosing on the clusters, can also contaminate milk.

One of the most common causes of contaminated milk is the failure to separate milk from cows that have been treated with veterinary medicines.

It should also be stressed that milk from animals that have had a positive reaction to a tuberculosis or brucellosis test must not be used for human consumption.

Cleaning guidelines

European regulations on producing top-quality milk highlight a number of areas where attention to detail should be observed by the farmer and the milking staff.

Prior to attaching the milking equipment to the cow, the foremilk from each animal must be stripped from the teats and examined for visible abnormalities. This test is also completed on robotic milking units by conductivity measurements. If anything unusual is detected, then the milk from this cow must be rejected and not allowed to enter the bulk collection tank.

It is a handy tip to farmers that they should wear rubber or vinyl gloves to milk the cows, which improves their own hygiene, and to wipe the cows’ udders and teats with paper towels before applying the milking equipment.

Keeping the milking equipment clean at all times is essential to prevent milk contamination. It is vital to keep the clusters clean, particularly to reduce the risk of infection between cows. It is recommended that the rubber components on the milking units, the hosing and clusters, should be replaced every 2,500 milkings. After the cow is milked, her teats can be dipped or sprayed with a disinfectant to reduce bacteria on the skin.

The milk must be sent to the bulk tank and cooled as soon as possible to minimise bacterial multiplication. There are many types of cooling systems available on the market, but using plate coolers is very common and can reduce cooling costs. The bulk tanks themselves must be cleaned and disinfected after each milk collection and monitored regularly for any problems.

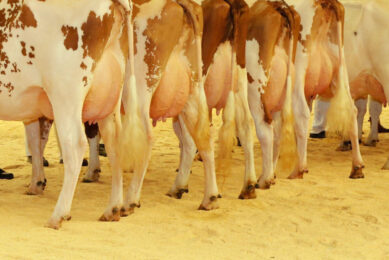

Cow cleanliness

As well as the cow needing to have a clean udder and teats, other parts of the animal also should be kept clean. Cows’ tails can play a part in contaminating milk or milking equipment, so it is good practice to trim or clip the tails at housing time and turn-out. A clean, trimmed tail also attracts fewer flies, improving overall hygiene.

Hair can also be trimmed from the cow’s belly and udder to help prevent soil or faeces sticking to these areas. Any dirt should be removed regularly, and cow brushes can be fitted in the cubicle house to encourage some personal grooming by the animal.

Washing out the system

All the equipment used in the milking parlour should be made from the appropriate food-grade material and kept clean. The milking system should be cleaned, disinfected and rinsed with clean water immediately after milking.

When each milking is complete, the exterior surfaces of the equipment should be scrubbed and rinsed with clean water. The interior of the system should then be rinsed, usually by a hot circulation clean. During the hot wash, the system should be pre-rinsed at 40°C to remove milk residues. Then, circulate a hot wash using an alkaline detergent steriliser for a minimum of five minutes and maximum of 10 minutes using 10–15 litres of water at 85°C per milking unit. Finally, rinse with clean cold water ideally containing 25 ml hypochlorite per every 40 litres of water.

Some farmers opt to carry out a cold wash to rinse the interior of the equipment, which is left in the system from one milking to the next then rinsed out prior to the next milking.

General hygiene

Dairy farmers must also take measures to control insects, birds and rodents in their barns to help prevent contamination. These can be a serious problem on some farms where feed is left out in the open and not covered.

When it comes to animal health, cows must be isolated if they are infected, or suspected of being infected, with any disease that could be transmitted to humans through milk.

Specific detailed records must be kept on feed supplies, on veterinary products and disease that may affect the safety of the milk, and on any results of samples and checks of animals or their products.

Most countries will have their own set of regulations that dairy farmers must follow in order to remain in food production, but they should be pretty similar.

Government inspectors will visit farms unannounced on an annual basis to make sure farmers are following the rules. Inspectors will also visit farms if there are any ongoing or recurring problems, such as high somatic cell counts.